Laser-adjusted tonearm operation is based on a level principle and helps to determine when tonearm mounting surface is parallel to the headshell (cartridge mounting) surface.

When using laser-adjusted tonearm, it is possible to adjust VTA and azimuth very quickly, comfortably and precisely after changing LP with different thickness or switching cartridges.

Laser beam a is adjusted so, that when it points to the point A on the scale c of the headshell b (Fig. 1, Fig. 2), the tonearm armwand is parallel to the tonearm mounting surface and a platter, i.e. VTA is adjusted to zero position.

If laser beam points above the point A (Fig. 3), tonearm must be lowered until the beam appears at the point A.

If laser beam points below the point A (Fig. 4), tonearm must be raised until the beam appears at the point A.

Headshell (cartridge mounting) plane is parallel to tonearm mounting/platter plane if, after turning the tonearm, laser beam a points to the point B, (Fig. 5, Fig. 6). That means azimuth is adjusted to zero position.

If laser beam does not appear in point B, azimuth must be adjusted accordingly.

There are lots of talks in the industry on the best armtube material, whether wood is better than Aluminum, or maybe Carbon fiber is the perfect material and so on.

To find out who's right and which material is perfect for hi-fi tonearm armtube, we decided to conduct a little research.

We hope that results of our investigation will help you understand armtube material impact to the tonearm's sound and help choosing tonearm in armtube material perspective.

The Background

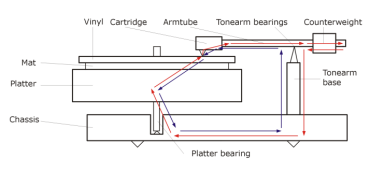

Figure 1 shows, why tonearm's sound depends on armtube material (and why turntable sound quality depends on mat material).

Fig. 1. Acoustic vibration spreading through the sound system

Stylus, while moving in the vinyl's groove, not only produces the musical signal, but also oscillates the cartridge itself. The oscillation (shown in red arrows) can be transferred through the armtube, partially reflect from the counterweight, and through the tonearm bearings, tonearm support, chassis, platter bearings, platter, mat and vinyl return back to the stylus. On the other hand, stylus causes vinyl plate vibrations (blue arrows), which, through the mat, platter, platter bearings, chassis, tonearm support, tonearm bearings and armtube, return to the stylus again.

The interference of these two acoustic vibrations can slightly impact the sound quality. Armtube material can suppress these parasitic accoustic vibrations (and of course, tonearm's effective mass depends mainly on armtube material).

The Gear

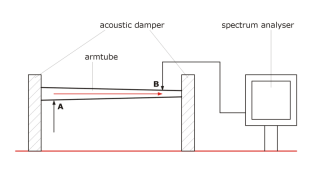

To carry on with the research, we built the device shown in Figure 2 (you can see its picture in the top-right of the article).

Fig. 2. Armtube testing device scheme

It consists of two acoustic dampers, holding the armtube; at the point A a broadband acoustic signal is fed; at the point B, it is registered using the broadband acoustic receiver and then passed to the spectrum analyzer.

The Wood

We acoustically tested following armtube materials:

- Western redcedar,

- Ebony Macassar,

- Cocobolo,

- Pernambucco,

- Pao Ferro,

- Panzerholtz (Tankwood).

Also for comparison we carried the same test to Carbon fiber, Fiberglass and Aluminum arms.

Figure 3. Wood samples tested (left to right): Panzerholtz (Tankwood), Western redcedar + C37, Pau Ferro, Pernambucco, Cocobolo, Ebony Macassar, Western redcedar

The Result

As you can see from the graphs on the right side of an article, woods with closest-to-perfect characteristics are Redcedar, Pernambucco and Panzerholz. They don't have clearly expressed resonant frequencies, and their sound damping characteristics are close to exponential function.

Results of our test are basically same to some audiophile opinion, that tonearms with Redcedar and Pernambucco wands produce very clean, transparent and deep sound. Meanwhile, even if tests show Panzerholtz being nearly perfect material for the arm, audiophile opinions on it are different.

Here you can find a few pictures of our workshop, lab equipment and testing tools. And we have quite interesting ones here...

For example, our Griffin turntable, used primarily for tonearm tests, features two stationary towers for tonearms and one spare place, where either tower for the third tonearm or motor can be mounted. Motor is mounted when we are carrying motor tests, i.e. validating motor speed etc.

We also built a device for tonearm armtube sound properties test. Everyone knows, or might guess, that wooden arm sounds better than one made of metal, but how to prove it? So, to check if wood is really better than a metal, also to compare wood with other materials (e.g. fiberglass) and different wood kinds itself, we made a quite simple yet interesting device. Its working principles will be described further in an article devoted to armtube material tests.